Kamco

Lime Rust Corrosion Cleaning Machines, Chemicals and Accessories

1-Why Choose Kamco?

Kamco machinery and chemicals are used for cleaning sludge, lime, rust and corrosion residues in heating and cooling systems. Kamco machinery and chemicals have many advantages over their competitors. Kamco machinery, chemicals and accessories have been manufactured in the UK since 1992.

2- What are Kamco's advantages over its competitors?

* In Kamco Chemical Washing Machines, the tank and pump consist of one piece. There is no need for fasteners. You can use it safely for many years.

* The material used in the body of Kamco Chemical Washing Machine is made of polypropylene. Resistant to all acid, base and chlorine based chemicals.

* In Kamco Chemical Washing Machine, there is no seal and gasket between the pump and the electric motor. There is no leakage of liquid from the pump to the electric motor. It is therefore very robust.

* Kamco Chemical Washing Machine can work wet and dry. The risk of failure is therefore minimized.

*Kamco Chemical Washing Machine operates at higher flow rate than its competitors. This not only shortens the cleaning time but also ensures better cleaning.

* In Kamco Chemical Washing Machine, two-way washing can be done with a single valve. Thanks to the reverse flow valve, it increases cleaning performance and provides convenience during cleaning.

* In Kamco Chemical Washing Machine, clean water supply, discharge and circulation processes are controlled by valves on the machine.

* Kamco Chemical Washing Machine can be used safely in all acids. It is also suitable for sterilization.

* Connection elements suitable for many installations are available.

* Maintenance free.

* Compact and portable.

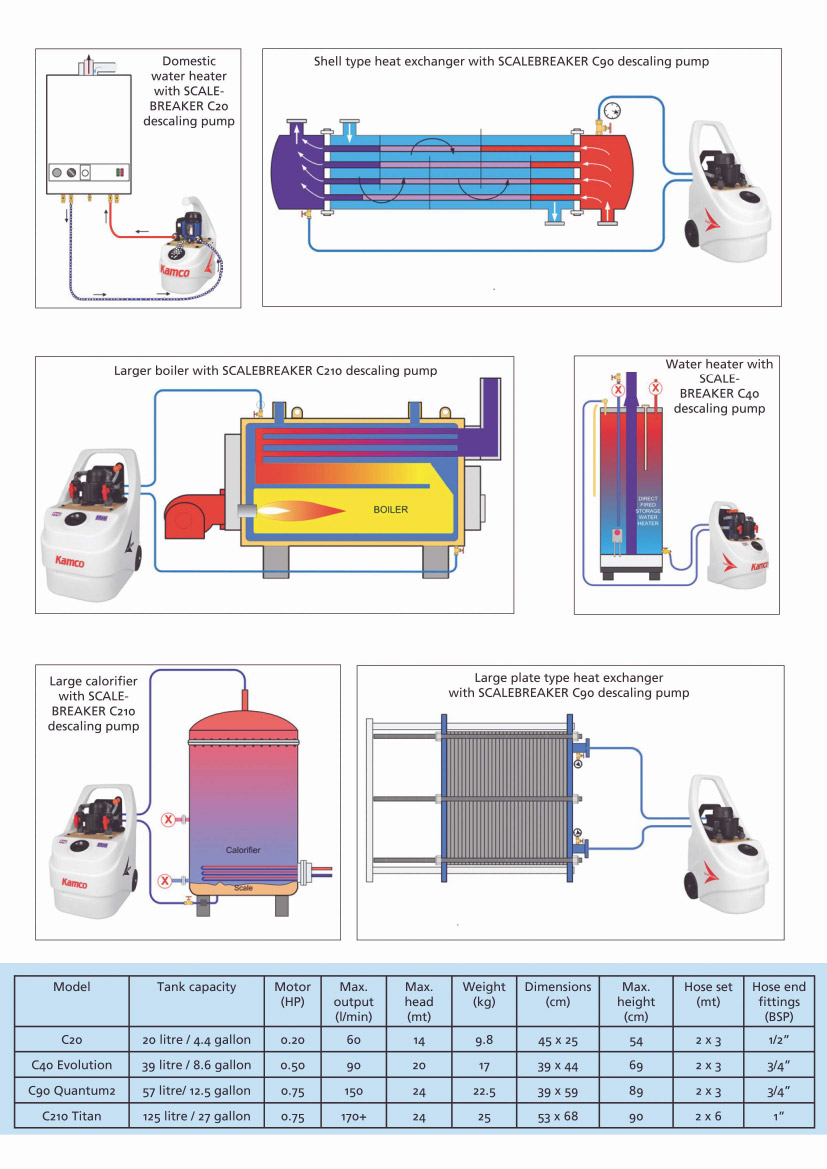

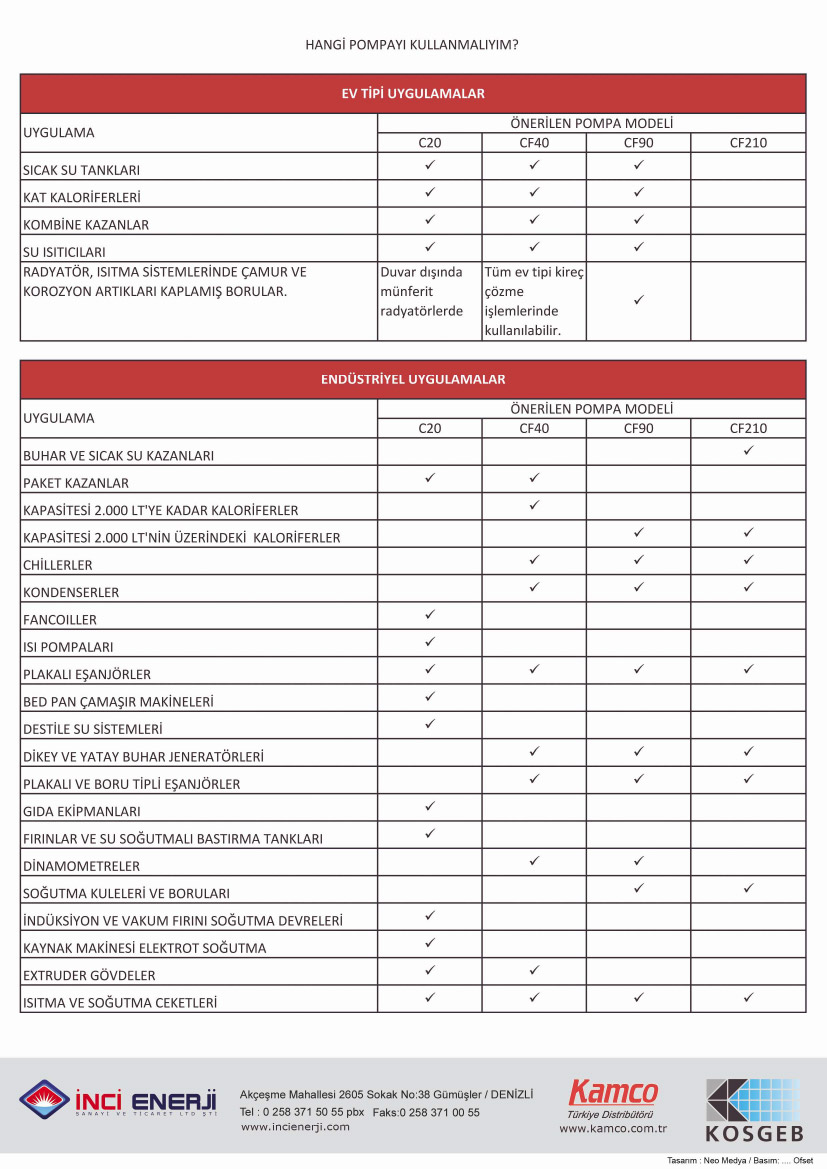

3-Use Areas

- Steam Boiler Cleaning

- Steam Generator Cleaning

- Air Dryer Heat Exchanger Cleaning

- Chiller Systems Cleaning

- Plastic Injection Molding Cooling Ducts Cleaning

Plate Heat Exchanger and Tube Heat Exchanger Cleaning:

- Heating Exchangers Cleaning

- Body Tube Heat Exchangers Cleaning

- Steam Exchangers Cleaning

- Biogas Heat Exchangers Cleaning

- Oil Cooling Heat Exchangers Cleaning

- Cleaning Brazed Heat Exchangers

- Waste Heat Recovery Heat Exchangers Cleaning

- Ship & Marine Heat Exchangers Cleaning

- Geothermal Heating Heat Exchangers Cleaning

- Pool Heating Exchangers Cleaning

- Cleaning Solar Heat Exchangers

- Sludge Exchanger Cleaning

- Hot Oil Heat Exchangers Cleaning

- Acid Cooling Heat Exchanger Cleaning

- Rolling Oil Cooling, Boron Oil Cooling, Mold Cooling, Heat Exchangers Cleaning

Radiator Cleaning:

- Heating Radiator Cleaning

- Cooling Radiator Cleaning

- Engine – Generator Cooling Radiator Cleaning

- Hot Oil Radiator Cleaning

- Steam Radiator Cleaning

- Ship Kuleri Cleaning

- Hot Oil Radiator Cleaning

- Water Cooling Tower Radiator Cleaning

Building Heating Systems Cleaning

- Steam Boiler Cleaning for Heating and Industry

- Boiler Tank Cleaning

- Central Heating System Cleaning

- Underfloor Heating Systems Cleaning

- Boiler system Lime and Corrosion Cleaning

- Heating systems- Heating radiators – Honeycomb Cleaning

- Cleaning of contaminants occurring in the serpentines of Fancoil Units